Xuchang Yuto is a leading domestic high-end brand packaging total solution provider, serving dozens of the Fortune 500 corporations and hundreds of high-end brands‘ customers. With strong production capacity and fine production management, Xuchang Yuto has provided professional, competitive packaging products, solutions and services for customers in the consumer electronics, massive health, alcohol and tobacco, cosmetics and food industries, committed to continuously enhancing the brand value for customers. Among the long list of strong and excellent customers are Foxconn, Intel, Philips, Brother, Microsoft, Samsung, SONY, Huawei, TCL, Asus and ZTE.

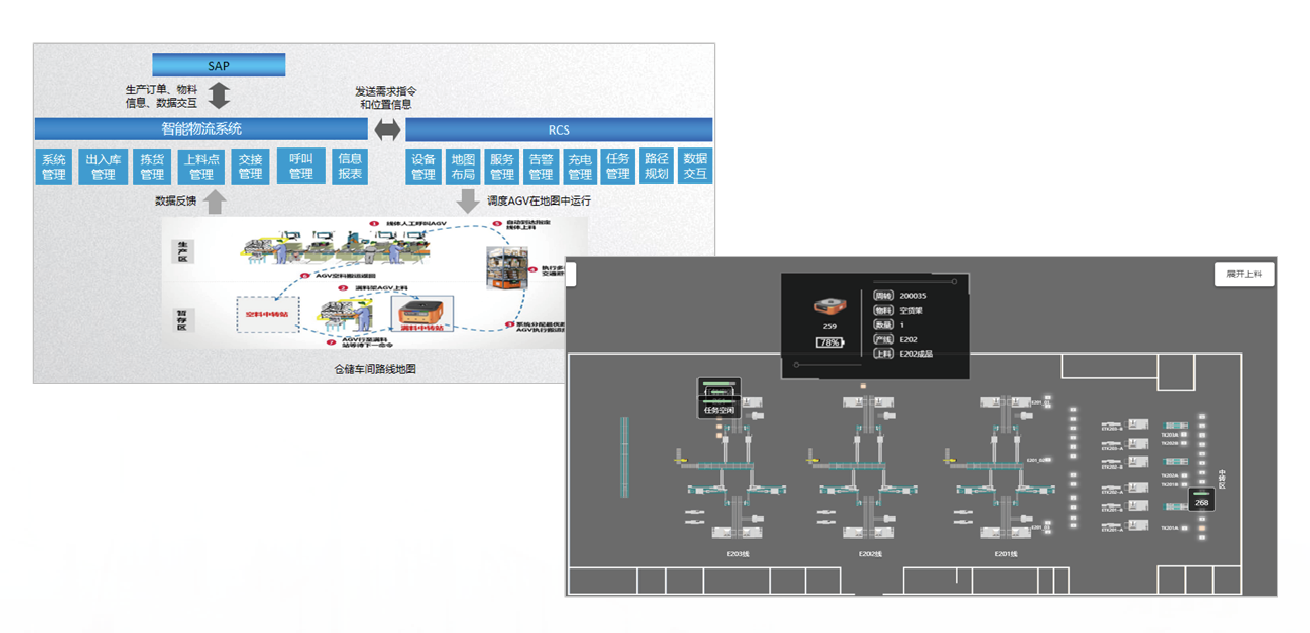

1. By building a heterogeneous platform of the system and integrating system resources of the enterprise, the RCS and WMS are connected. Unmanned operations are carried out in the warehouse. The incoming and outgoing of WIP and finished products are carried out through the intelligent logistics system triggering relevant instructions and dispatching AGV to move the racks to the sorting station for sorting and inventory-taking.

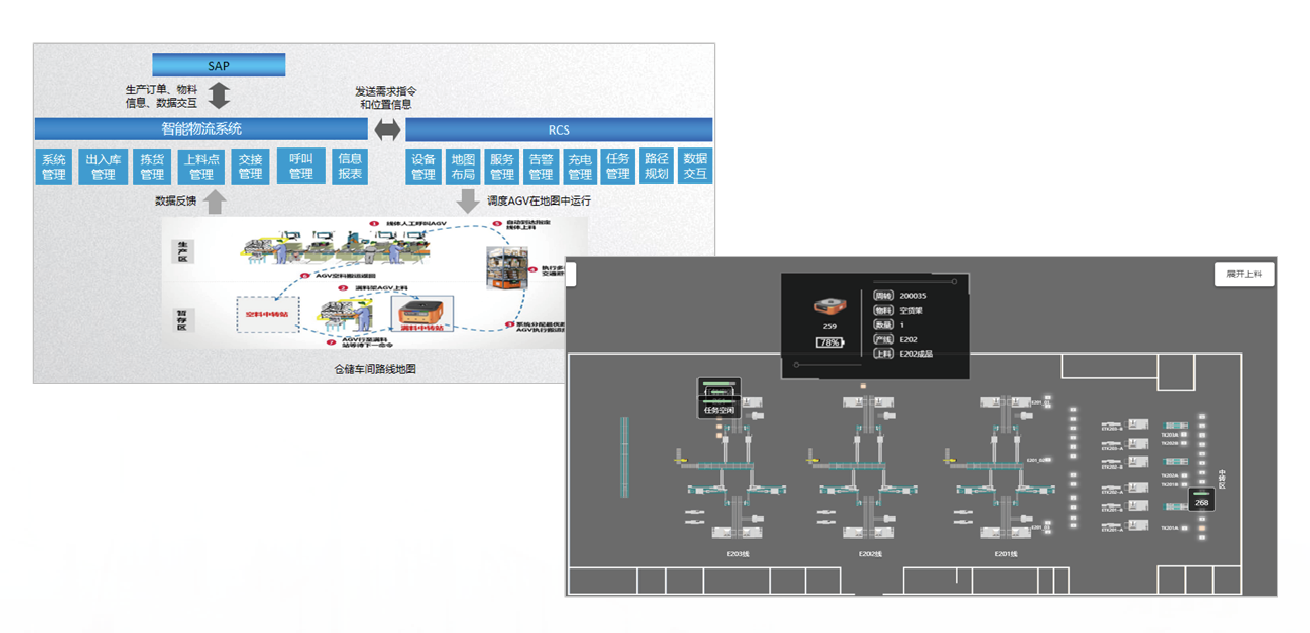

2. AGVs are imported to automatically transport parts to the appropriate processing equipment at the appropriate time based on the product process route and machine tasks. Through the real-time monitoring kanban and workshop CAD background diagram, the AGV operation route is monitored in real time to display the battery level, serial number, materials loaded and quantity, rack number and other relevant information, so that the transportation information of the materials can be promptly viewed by the production lines and warehouse.